细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

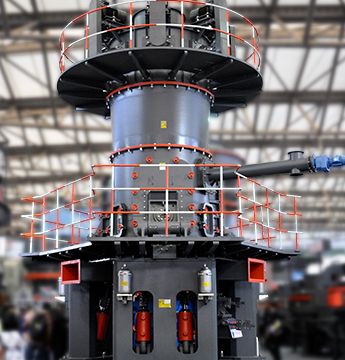

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Corn Dry Grind To Ethanol

Composition of corn drygrind ethanol byproducts: DDGS,

2008年8月1日 The dry grind ethanol process is one of two processes for commercial fuel ethanol production from grain The dry grind process, unlike the wet milling process, does not 2016年10月24日 Conventional corn drygrind ethanol production process requires exogenous alpha and glucoamylases enzymes to breakdown starch into glucose, which is fermented to ethanol by yeast This study evaluates the Drygrind processing using amylase corn and 2004年12月14日 Current technologies allow for 25 gallons (wet mill process) to 28 gallons (dry grind process) of ethanol (1 gallon = 3785 l) per bushel of corn Valuable coproducts, Biotechnological processes for conversion of corn into ethanol2006年5月1日 The corn drygrind process is the most widely used method in the US for generating fuel ethanol by fermentation of grain Increasing demand for domestically produced Modeling the process and costs of fuel ethanol production by the corn

Production of Ethanol from Corn and Sugarcane Bioenergy

2008年5月1日 Cornstarch is processed to ethanol by either the drygrind or wetmilling process The two processes differ in how the kernel is initially treated to access starch for enzymatic 2021年5月4日 In bioethanol plants, corn (2540 kg) is transformed into ethanol (118 liters), DDGS (77 kg), corn oil, and carbon dioxide (CO 2) Drygrind fuel ethanol production is the Corn distillers dried grains with solubles: Production, Although the corn oil does not take part in starch fermentation into ethanol, the implication of the front‐end degermination in dry‐grind corn process on downstream product recovery is anFlow chart of typical corn dry grind fuel ethanol Figures 710a and 710b show the process steps for each wet and dry milling For wet milling, the corn kernels are broken down into starch, fiber, corn germ, and protein by heating in the sulfurous acid solution for 2 days The starch is 73b: How Corn is Processed to Make Ethanol

.jpg)

New technologies in value addition to the thin stillage from corn

The environmental impacts of a potential hybrid energy system, combining distiller’s corn oil extraction from the drygrind ethanol process, with the transesterificationbased reaction and 2018年12月1日 However, corn kernel fractionation in the dry grind process requires high capital cost and retrofitting in the dry grind plant (Kim et al, 2016) Addition of cellulase enzymes during saccharification and fermentation (SSF) is a potentially costeffective approach to convert corn fiber into ethanol in dry grind process as minimal changes in the Increasing ethanol yield through fiber conversion in corn dry grind 2019年9月1日 Use of corn fractionation techniques in dry grind process increases the number of coproducts, enhances their quality and value, generates feedstock for cellulosic ethanol production and potentially increases Impact of Fractionation Process on the Technical 2006年5月1日 A process and cost model for a conventional corn drygrind processing facility producing 119 million kg/year (40 million gal/year) of ethanol was developed as a research tool for use in evaluating new processing technologies and products from starchbased commoditiesThe models were developed using SuperPro Designer ® software and they handle the composition Modeling the process and costs of fuel ethanol production by the corn

.jpg)

Drygrind processing using amylase corn and superior yeast

2016年10月24日 Conventional corn drygrind ethanol production process requires exogenous alpha and glucoamylases enzymes to breakdown starch into glucose, which is fermented to ethanol by yeast This study evaluates the potential use of new genetically engineered corn and yeast, which can eliminate or minimize the use of these external enzymes, improve the 2008年8月1日 Fuel ethanol production from corn grain in the US exceeded 49 billion gallons in 2006 Of that production, 82% was from facilities employing some variation of the drygrind process for ethanol production (Renewable Fuels Association, 2007)Drygrind processes are characterized by a lack of a steeping step at the front end of the process, a hallmark of wet Composition of corn drygrind ethanol byproducts: DDGS, 2020年1月1日 Commercial production of fuel ethanol in the United States involves breaking down the starch present in corn into simple sugars (glucose), feeding these sugars to yeast (fermentation), and then recovering the main product (ethanol) and byproducts (eg, animal feed) Two major industrial methods for producing fuel ethanol are used in the United States: How fuel ethanol is made from corn ScienceDirect2021年5月1日 the corn dry grind process, while the wet mills contribute to only about 10% of the US ethanol production (Fang, 2017) The dry grind process is predominant because it is more effi(PDF) Corn Distillers Dried Grains with Solubles: Production

Corn distillers dried grains with solubles: Production,

2021年5月4日 Distillers dried grains with solubles (DDGS) are a primary coproduct of bioethanol plants of the conventional corn drygrind process With increasing cornbased ethanol production, DDGS production is increased, and it has become a global commodity Despite the high nutritional value of DDGS, however, its uses are still not fully explored2018年1月1日 Drygrind corn ethanol industry has become the second largest corn user in the United States, producing 90% of the ethanol in the US in 2015 This industry was very profitable in the past However, due to the sharp decline in crude oil price, the price of drygrind corn ethanol fell sharply in recent years (Irwin and Good, 2015, Wisner, 2015 Use of surfactant and enzymes in drygrind corn ethanol Graintoethanol production has increased steadily in the United States in the past few decades, which resulted in remarkable records in the availability of coproducts Drygrind is the most common method of ethanol production worldwide, which concentrates the corn and yeast nutrients in the downstream operations The ethanol coproducts have traditionally been a New technologies in value addition to the thin stillage from corn 2019年9月1日 In the conventional dry grind process, starch in the corn kernel is hydrolyzed to produce glucose and fermented into ethanol In addition to ethanol, Distiller’s dried grains with solubles (DDGS) and corn oil are coproducts of conventional dry grind process Unfermented components in corn dry grind process are recovered asEconomic Viability of Corn Dry Grind mdpires

Corn to Ethanol Indian Council of Agricultural Research

2020年3月28日 and Eckhoff 1996), COPE process (Cheryan 2002), enzymatic milling (Johnston et al 2003), dry grind and wet milling Both dry grind and wet milling processes are popular nowadays but most of the ethanol is produced by dry grind method only because it is less capital and energyintensive (Butzen and Haefele, 2008) Bio Fuel2023年9月1日 The drygrind ethanol process from corn leads to the fermentation of a viscous mash with all the corn kernel components grinded to a saccharified and liquefied mass, which possesses almost opposite characteristics as those earlier pointed for sugarcane Yet, against the technical odds, drygrind corn ethanol production accounts for over 90% of Utilization of coproducts from corn ethanol industry in a maximize phytate extraction from drygrind coproducts Materials and methods Sample collection, storage and chemicals WS, TS, WDG, CDS, and DDGS were obtained from a largescale drygrind corn ethanol plant located in the state of Iowa, USA All samples were stored in the refrigerator at 20 C prior to usePhytate extraction from coproducts of the drygrind 2006年5月1日 The corn drygrind process is the most widely used method in the US for generating fuel ethanol by fermentation of grain Increasing demand for domestically produced fuel and changes in the Modeling the process and costs of fuel ethanol production by the corn

.jpg)

A Laboratory Decanting Procedure to Simulate Whole

2009年8月26日 The corn fuel ethanol industry in the United States has expanded rapidly over the past 8 years In 2007, about 28 billion L (72 billion gal) of corn fuel ethanol was produced, which was more than four times the production in 2000 []Corn fuel ethanol is produced by two processes, the drygrind process and the wetmilling process2005年3月1日 Corn from an ethanol plant (commodity corn) and an identity preserved corn hybrid from a seed company (control corn stored at 4 °C) were used to study the effects of incoming corn on dry grind Effect of corn hybrid variability and planting location on dry grind 2008年10月7日 The effects of corn preparation and grinding methods on oil distribution between liquid and solid phases were studied and dry matter yield and oil partitioning in the thin stillage were highly positively correlated The majority of fuel ethanol in the United States is produced by using the drygrind corn ethanol process The corn oil that is contained in the coproduct, Effect of the corn breaking method on oil Semantic Scholar2011年11月3日 CHAPTER 3 DryGrind Production of Ethanol, Distillers Corn Oil, and Corn CoProducts 11 Drygrind Ethanol Production Particle size reduction of grain As shown in Figure 10, the initial step in ethanol production using drygrind technology is to reduce the particle size of corn by grinding it with a hammermill Hammermills crushCHAPTER 3 C H A GRAINS

.jpg)

Production of Ethanol from Corn and Sugarcane Bioenergy

2008年5月1日 Cornstarch is processed to ethanol by either the drygrind or wetmilling process The two processes differ in how the kernel is initially treated to access starch for enzymatic hydrolysis In addition to the use of sugar in ethanol production, wetmilled starch can also be sold as dried or modified corn starch, or converted enzymatically to 2018年5月1日 Use of amylase corn and superior yeast in the drygrind processing industry can reduce the total external enzyme usage by more than 80 %, and combining their use with in situ removal of ethanol during fermentation allows efficient highsolid fermentationFermentation technology to improve productivity in dry grind corn 2009年5月20日 ABSTRACT In 2008, the United States produced ethanol at a rate of 395 billion L/year; an additional 85 billion L/year capacity was under construction Kernel composition and physical properties are not correlated with ethanol yield A procedure that measured the potential of hybrids to produce ethanol would benefit corn seed companies, corn producers, and ethanol Development of an Ethanol Yield Procedure for DryGrind Corn 2018年1月20日 The ethanol yield of 042 L/kg of dry corn with about 80% ethanol conversion efficiency was 88% higher than that of the conventional process at 42% solids (022 L/kg dry corn)Fermentation technology to improve productivity in dry grind corn

Dry Grind Production of Ethanol from Corn : USDA ARS

Dry Grind Production of Ethanol from Corn: Computer programs which model the process and costs of ethanol production is available from the USDA'S Agricultural Research Service (ARS) A series of computer models of the ethanol process and production economics have been developed by ARS engineers conducting research to reduce ethanol costs These 1999年11月15日 A new process was developed to recover corn fiber from the mash before fermentation in drygrind ethanol production In this process, corn is soaked in water (no chemicals) for a short period of time and then degermed using conventional degermination millsRecovery of Fiber in the Corn Dry‐Grind Ethanol Process: A 2006年5月1日 While fuel ethanol production is an energyefficient process today, additional research is occurring to improve its longterm economic viability and three of the most significant areas of research are in the production of hybrids with a higher starch content or a higher extractable starch content, in the conversion of the corn kernel fiber fraction to ethanol, and in Modeling the process and costs of fuel ethanol production by the corn 2019年9月1日 Ethanol yields for plants processing 111311 MT corn/day were 372 to 40 million gal for wet fractionation and 373 to 313 million gal for dry fractionation, compared to 402 million gal for (PDF) Impact of Fractionation Process on the Technical and

Addition of cellulolytic enzymes and phytase for improving ethanol

2015年12月23日 The US corn production in 2014 was approximately 142 billion bushels, with roughly 30% utilized for ethanol production (NCGA, 2015) Ethanol has been the most significant source of total biofuel usage in the US (94%), of which about 82% is produced using corn drygrind process (Wang et al, 2009a)2010年9月18日 During the dry grind ethanol process, ground corn is fermented and the major coproduct is a feed called distillers dried grains with solubles (DDGS) This study investigated the changes that occur in the composition of corn oil that can be extracted from various process fractions during the dry grind ethanol process In the first part of this study, samples of distillers Changes in Lipid Composition During Dry Grind Ethanol Processing of Corn2018年12月1日 However, corn kernel fractionation in the dry grind process requires high capital cost and retrofitting in the dry grind plant (Kim et al, 2016) Addition of cellulase enzymes during saccharification and fermentation (SSF) is a potentially costeffective approach to convert corn fiber into ethanol in dry grind process as minimal changes in the Increasing ethanol yield through fiber conversion in corn dry grind 2019年9月1日 Use of corn fractionation techniques in dry grind process increases the number of coproducts, enhances their quality and value, generates feedstock for cellulosic ethanol production and potentially increases Impact of Fractionation Process on the Technical

Modeling the process and costs of fuel ethanol production by the corn

2006年5月1日 A process and cost model for a conventional corn drygrind processing facility producing 119 million kg/year (40 million gal/year) of ethanol was developed as a research tool for use in evaluating new processing technologies and products from starchbased commoditiesThe models were developed using SuperPro Designer ® software and they handle the composition 2016年10月24日 Conventional corn drygrind ethanol production process requires exogenous alpha and glucoamylases enzymes to breakdown starch into glucose, which is fermented to ethanol by yeast This study evaluates the potential use of new genetically engineered corn and yeast, which can eliminate or minimize the use of these external enzymes, improve the Drygrind processing using amylase corn and superior yeast 2008年8月1日 Fuel ethanol production from corn grain in the US exceeded 49 billion gallons in 2006 Of that production, 82% was from facilities employing some variation of the drygrind process for ethanol production (Renewable Fuels Association, 2007)Drygrind processes are characterized by a lack of a steeping step at the front end of the process, a hallmark of wet Composition of corn drygrind ethanol byproducts: DDGS, 2020年1月1日 Commercial production of fuel ethanol in the United States involves breaking down the starch present in corn into simple sugars (glucose), feeding these sugars to yeast (fermentation), and then recovering the main product (ethanol) and byproducts (eg, animal feed) Two major industrial methods for producing fuel ethanol are used in the United States: How fuel ethanol is made from corn ScienceDirect

.jpg)

(PDF) Corn Distillers Dried Grains with Solubles: Production

2021年5月1日 the corn dry grind process, while the wet mills contribute to only about 10% of the US ethanol production (Fang, 2017) The dry grind process is predominant because it is more effi2021年5月4日 Distillers dried grains with solubles (DDGS) are a primary coproduct of bioethanol plants of the conventional corn drygrind process With increasing cornbased ethanol production, DDGS production is increased, and it has become a global commodity Despite the high nutritional value of DDGS, however, its uses are still not fully exploredCorn distillers dried grains with solubles: Production, 2018年1月1日 Drygrind corn ethanol industry has become the second largest corn user in the United States, producing 90% of the ethanol in the US in 2015 This industry was very profitable in the past However, due to the sharp decline in crude oil price, the price of drygrind corn ethanol fell sharply in recent years (Irwin and Good, 2015, Wisner, 2015 Use of surfactant and enzymes in drygrind corn ethanol

液压式重晶石磨粉机价格

--片麻岩石灰石方解石粉碎

--关于采矿权是否强制执行关于采矿权是否强制执行关于采矿权是否强制执行

--方解石矿石磨粉机型号

--江西省锂矿粉碎设备大市场公交线路

--中国煤矿机械制造

--重钙磨粉机雷蒙机150250氟石膏

--广西钦州内哪里有大的工业磨粉机厂家呢

--膨润土自动加工设备

--台时100吨水泥磨多大

--湖南张家界市磨方解石的设备生产线

--供电设备铝土矿洞

--浙江绍兴市方解石磨机每小时产量

--粉磨沙设备链条

--韩国悍马粉磨机

--电厂碎煤机震动

--兰州石油焦粉碎机

--干粉石灰石在太原市的发展前景干粉石灰石在太原市的发展前景干粉石灰石在太原市的发展前景

--广东广州龙湖粉碎机公司,联系我们

--乌海市天宇化工

--时产1300吨菱镁矿石灰石重晶石磨粉机

--黎明重工HP160粉碎机

--三明市二氧化硅磨粉机

--方解石矿方解石石灰石粉碎

--永辉有磨粉店吗?

--矿山振动分级筛

--石灰石粉碎机冶炼废渣处理厂怎么申请

--如何摆脱雷蒙磨噪声过大的问题如何摆脱雷蒙磨噪声过大的问题如何摆脱雷蒙磨噪声过大的问题

--奥贝玛矿石磨粉机工作原理图

--雷蒙磨过了可以直接进雷蒙磨吗

--