细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

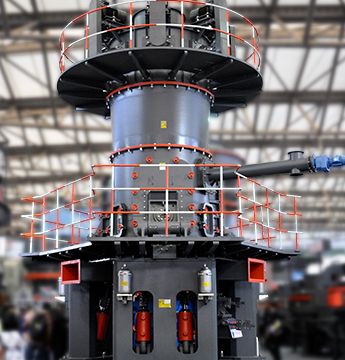

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Cement Raw Material Grinding Mill

.jpg)

OK™ Raw and Cement Mill FLSmidth Cement

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest Guilin Hongcheng cement raw materials mill has stable performance and high quality, basically realizes dustfree processing and saves operating costs Toggle navigation Homevertical raw mill for cement raw materials milling hcm2023年8月17日 The OK mill efficiently grinds even the hardest raw materials and blended cements with a wide range of additives such as slag, pozzolana, limestone and fly ashOK™ mill The most reliable and efficient mill for raw and 2017年6月19日 The modular vertical roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically designed to meet the Grinding process optimization IEEE Xplore

2 µm 5 µm Loesche

2017年8月11日 Loesche mills have also been used for grinding cement raw material The biggest breakthrough in this field of application took place in the 1960’s Soon after this the Grinding of cement raw material – material separation in cyclones The cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill For drying the material, hot gases are directed into the mill Product Raw mills for all requirements Gebr Pfeiffer2021年3月12日 common solution to grind raw materials and cement Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product BALL MILLS Ball mill optimisation Holzinger Consulting2016年10月5日 Energyefficient equipments such as highpressure grinding rolls, vertical roller mills, CKP pregrinders, Cemex ® mills and Horomills ® are used at both finish grinding of cement and raw materialgrinding stages due to EnergyEfficient Technologies in Cement

.jpg)

PFEIFFER MILLS FOR THE CEMENT INDUSTRY

2022年5月18日 ensuring economical grinding of cement raw material, cement clinker, granulated blastfurnace slag, pozzolana, other additives, and coal Highest plant availability, 2015年4月1日 Highlights • A raw meal ball mill classification circuit was modelled and simulated • 23% capacity increase could be achieved in cement throughput when predrying Optimization of a fully airswept dry grinding cement raw Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials Raw Mill, Cement Raw Mill, Raw Mill In Cement 2021年3月12日 common solution to grind raw materials and cement Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications This paper will focus on the ball mill grinding process, its tools and optimisationBALL MILLS Ball mill optimisation Holzinger Consulting

Review on vertical roller mill in cement industry its

2021年1月1日 The metal wear of the unit product is low The wear is generally only 5 to 15 g/t, and even only 3 to 5 g/t Therefore, the wearing parts have long service life; the metal powder resulted from metal wear is small, so vertical roller mills can also grind the white cement raw material [15], [16] •2023年8月17日 Mill (VRM) designs for raw, fuel and cement grinding for several decades The OK™ mill has been FLSmidth’s standard cement VRM since 1993 Since its introduction, the OK mill has proven to be the most efficient cement for the hardest materials The OK™ raw and cement mills are available in all sizes 0 200 400 600 800 1000 1200 1400 OK™ mill The most reliable and efficient mill for raw and Raw mill is the grinding equipment applied in the raw material preparation processIn the wet process of cement production, raw materials should be ground into raw slurry with a water content of 30% – 40% While in the dry process of cement production, they will be ground into dry powder in a cement raw millCement Mill Cement Grinding Machine AGICO Cement Grinding MillThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a Vertical Roller Mill Operation in Cement Plant

.jpg)

2 µm 5 µm Loesche

2017年8月11日 The springloaded roller grinding mill for grinding coal was intro duced by Loesche in the 1920’s Since the end of the 1930’s Loesche mills have also been used for grinding cement raw material The biggest breakthrough in this field of application took place in the 1960’s Soon after this the cement industry expressed the desire toWhether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performanceVertical roller mills FLSmidth Cement2024年10月16日 Ball mills are one of the most commonly used types of equipment for cement grinding They utilize steel balls as grinding media to crush and grind the raw materials into fine powder The process operates in a continuous cycle: Material Feeding: The raw materials are fed into the mill Grinding: The steel balls pulverize the materials by Grinding in Cement Manufacturing: Key Process, Types of Mills2017年8月12日 vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and mostPROCESS OPTIMISATION FOR LOESCHE GRINDING

From raw materials to cement

2022年2月12日 The most important raw materials for making cement are limestone, clay and marl These are extracted from quarries by blasting or by ripping using heavy machinery Wheel loaders and dumper trucks is prepared using metering devices Roller grinding mills and ball mills grind the mixture to a fine powder at the same time as drying it, before 2024年2月23日 The operation of the cement raw mill is a critical step in cement production By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement ingredients and burn more evenly How Does a Raw Mill Work in a Cement IndustryFor raw material grinding a quadropol® vertical roller mills QMR² 45/23 was contracted to serve the kiln line, while for cement grinding two identical QMC² 45/23 were considered for grinding different cement types The request for interchangeable parts for the three mills was fulfilled and represents still a holistic approachquadropol® thyssenkrupp Polysius Grinding Technologies2019年4月23日 Introduction Portland cement underpins modern global development As such, it is the most abundantly produced material in the world (Deolalkar Citation 2016)The world has an abundance of the primary raw materials for cement manufacturing and, compared to other construction materials, cement’s cost is low and it has good durability (Hewlett Citation 2003)An overview of alternative raw materials used in cement and

.jpg)

Modeling Based on the Extreme Learning Machine for Raw Cement Mill

2015年1月1日 The raw material grinding in the cement mill for production of cement is one of the most energydemanding processes in cement industry In cement plants, 50–60 % of the total energy consumption is due to grinding of raw materials The process of parameter adjustment requires too much of human intervention Online measurement of quality 2023年8月17日 Vertical Roller Mills (VRMs) have been the standard option for raw materials grinding in the cement industry for several decades FLSmidth has supplied the global cement industry with leading VRM FLSmidth’s modular design uses the same common OK mill parts for both raw and cement applicationsOK™ raw mill Reliable and efficient raw material grinding5 天之前 The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesche‘s pioneering engineering knowhow CEMENT BLAST FURNACE SLAG CEMENT RAW MATERIALCement Industry Loesche2022年5月9日 Lin, X Liang, J Modeling based on the extreme learning machine for raw cement mill grinding process in Proceedings of the 2015 Chinese Intelligent Automation Conference 129–138 (2015)Modeling of energy consumption factors for an industrial cement

.jpg)

Raw Mill Moisture Content Management: A

Managing moisture content in raw materials is a critical aspect of cement production The efficiency and quality of the raw milling process significantly depend on maintaining optimal moisture levels Hot gas generators: These 4 天之前 One of the fundamentals of cement manufacturing is to ensure the right chemical composition of the cement raw mill A raw mill with a superior fineness and wellcontrolled chemical composition using as advanced control Raw Mill in Cement Plant Cement 2016年1月20日 In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system 248 t, 469 t, and 341 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages; waste gases account for Analysis of material flow and consumption in cement production 2024年4月10日 SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d The vertical grinding mill is utilized for the grinding of raw materials, mixed cement, and slag powderVertical Roller Mill for Cement Raw Material SINOMALY

.jpg)

A Survey and Analysis on Electricity Consumption of Raw Material Mill

2021年1月22日 Retention time in cement grinding which is the time taken by material to attain the required particle size before it reaches the mill outlet, can be reduced by the use of a closed mill grinding 2015年4月1日 1 Introduction Airswept raw meal ball mills introduced by the cement mill manufacturers FLSmidth ® (Smidth, 2002), Polysius ® (Polysius, 2002) and KHD Humboldt Wedag® are the most commonly used onesKHD Humboldt Wedag® manufactured fully airswept raw meal mills which have two compartments used for drying and grinding processesOptimization of a fully airswept dry grinding cement raw Individual large air swept Vertical Mills are preferred over ball mills for better grinding efficiency and to get an advantage in power consumption Cement raw material is the mixture of mainly Limestone other constituent such Iron oxide, Shale etc having different moisture contain depending on composition depositVRM – AMCL Machinery LimitedGrind cement raw materials, clinker, and slag, as well as minerals, with a roller press from the technical leader Product Features When compared with other grinding options, such as ball mills and vertical roller mills, the roller press is the most energyefficient grinding system on the market Which means lower energy bills for you So Roller Press KHD Humboldt Wedag

Preparation Of Cement Raw Material Cement Mill, Cement

Mixing: according to the requirement of clinker, compound desired raw material for cement production line Grinding: grinding all materials into required fineness by cement mill Cement ball mill and vertical cement mill are two common types Homogenizing: homogeneous kiln feed is the precondition of clinker production, so homogenization of raw 2019年10月11日 The cement roller press and cement mill are used to grind the cement raw material to the required particle size and packaging There are two types of cement mill including a ball mill and vertical cement mill The packing machine is used to pack the finished cement product into a bag according to a certain weightCement Grinding Plant Overview Cement Grinding Unit Cement Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials Raw Mill, Cement Raw Mill, Raw Mill In Cement 2021年3月12日 common solution to grind raw materials and cement Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications This paper will focus on the ball mill grinding process, its tools and optimisationBALL MILLS Ball mill optimisation Holzinger Consulting

.jpg)

Review on vertical roller mill in cement industry its

2021年1月1日 The metal wear of the unit product is low The wear is generally only 5 to 15 g/t, and even only 3 to 5 g/t Therefore, the wearing parts have long service life; the metal powder resulted from metal wear is small, so vertical roller mills can also grind the white cement raw material [15], [16] •2023年8月17日 Mill (VRM) designs for raw, fuel and cement grinding for several decades The OK™ mill has been FLSmidth’s standard cement VRM since 1993 Since its introduction, the OK mill has proven to be the most efficient cement for the hardest materials The OK™ raw and cement mills are available in all sizes 0 200 400 600 800 1000 1200 1400 OK™ mill The most reliable and efficient mill for raw and Raw mill is the grinding equipment applied in the raw material preparation processIn the wet process of cement production, raw materials should be ground into raw slurry with a water content of 30% – 40% While in the dry process of cement production, they will be ground into dry powder in a cement raw millCement Mill Cement Grinding Machine AGICO Cement Grinding MillThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a Vertical Roller Mill Operation in Cement Plant

.jpg)

2 µm 5 µm Loesche

2017年8月11日 The springloaded roller grinding mill for grinding coal was intro duced by Loesche in the 1920’s Since the end of the 1930’s Loesche mills have also been used for grinding cement raw material The biggest breakthrough in this field of application took place in the 1960’s Soon after this the cement industry expressed the desire toWhether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performanceVertical roller mills FLSmidth Cement2024年10月16日 Ball mills are one of the most commonly used types of equipment for cement grinding They utilize steel balls as grinding media to crush and grind the raw materials into fine powder The process operates in a continuous cycle: Material Feeding: The raw materials are fed into the mill Grinding: The steel balls pulverize the materials by Grinding in Cement Manufacturing: Key Process, Types of Mills

供4R3220雷蒙磨粉机

--江苏南通市白云石立式磨产品优势

--灰岩加工碳酸钙

--传统的工业磨粉机厂家经营模式

--矿石制粉厂需要那些设备

--天津哪里卖柴田矿石磨粉机配件

--每小时产52T重钙石头磨粉机

--优质振动给料器

--矿山施工设备矿山施工设备矿山施工设备

--中速磨煤辊

--重钙粉加工设备技术要求

--淄博粉煤灰

--重庆矿山焙烧锂辉石市场

--石膏工艺

--旱地生石灰石粉机旱地生石灰石粉机旱地生石灰石粉机

--关于石灰石场对水质影响的情况报告

--开水泥店需要多少钱

--上海雷蒙磨图纸哪里有卖

--时产500800吨钙粉粉碎机代理价

--煤矸石制粉多少送检一批

--保定安国现磨碳酸锂

--方解石矿机械

--4.3米水泥粉磨设备4.3米水泥粉磨设备4.3米水泥粉磨设备

--钙粉粉碎机下

--整套矿粉制粉设备

--矿石磨粉机厂家

--日产2500吨锆英石广西雷蒙磨

--怎样把粉磨得很细

--粉碎粉尘排放速率

--有人要全新大理石

--